The first floor (not the ground floor!) has the walls built. Those block layers completed the first floor in ONE DAY! They get paid by the block. The more they do the more they get paid.

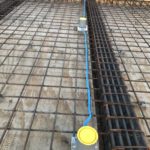

The contractor placed all the rebar to get ready for the second floor concrete pour. I realized that the plan called for two floor electrical boxes and an electrical connection for the kitchen island. After not getting any response as to who will do it, I did it. I’m sure it would have taken the electrician less time but I know it was done. After, I told the contractor what I did. Then he contacted me to tell me that the electrician was going to be there the next day. Communication was lacking…

After the block walls went up we needed to wait awhile for the second floor to be poured. The pour went well. They poured about 65 yards of concrete in a few hours. Sometimes two concrete trucks at a time were feeding concrete to the pumper. There were about twelve people working at one time. Concrete delivery guys, pumper controller, concrete hose managers, concrete spreaders, and concrete finishers.

Later that day I went back as the concrete was set and watered down the new concrete. The heat steals moisture from the fresh concrete. Its a good idea to do it. I don’t know if my meager efforts really helps.

I expected the work to slow down after this pour. But, the same afternoon as the pour, the concrete block as delivered. The day after the pour the lift rig placed all the concrete block on the second floor, ready for block placement tomorrow. The contractor is now measuring out all the window and door locations before the block is laid tomorrow.

The contractor is currently completing the framing for the concrete work of the second floor. They are doing things differently by finishing the second floor with poured concrete rather than concrete block. I’m not sure why they are doing it that way but they are. The arches at the tops of the exterior balcony arches are to be made out of wood. I thought they would be made of formed concrete but, I am wrong again. I am going to add additional plastic sleeves for electrical service that never made it into the plans. I intend to have a TV and other exterior electrical appliances out side as well. I need to make sure the sleeves are in first rather than chip out poured concrete!